Pipeline Cleaning

The Process

Firstly, Proline will survey the area to be rehabilitated and consult

the drawings if they are available. Following this, we will confer

with you the "client" and decide were the best possible sites are for

access pits.

Cleaning.

When the access pits have been excavated and a short pipe

nipple has been removed or a manhole access point has been

cut into the top of the pipe we begin the process of removing

the debris from the interior of the pipe. There are four ways

of managing this process and pipe size is a critical factor

in deciding which method is the most appropriate.

Rackfeed.

This method is most effective on pipe size ranging from 3”(75mm)-12”(300mm).

The Rackfeed consists of a Hydraulic drive, which rotates

and moves backwards and forwards. The rotation is to rotate

the special interlocking steel rods, which are connected to

the warhead, and flails; this process cleans the interior

of the pipe. The backward and forward motions are to force

the warhead up or down the pipe.

Drag Scraping.

At each access pit at the ends of the run to be cleaned we

set up a winch. Once the steel cable is through the pipe scrapers

are attached and these repeatedly pull backwards and forwards

until the debris is completely removed from the pipe wall,

we then attach a series of squeegee’s these are also

pulled backwards and forwards until all debris is removed

from the interior of the pipe.

Hydraulic Cleaning.

With this system we use a specially adapted scraper. We remove

a pipe nipple and introduce the cleaner into the pipe then

we replace the pipe nipple. At the far end of the run, this

can be as much as 15 Kilometers away we have a catchment nipple,

once this is in place we slowly increase the water pressure

within the main, as the pressure increases the scraper begins

to move, thus removing the debris from the pipe wall, the

passing water pushes the debris forward. Once the cleaner

gets to the end of the run the scraper is retained within

the catchment nipple.

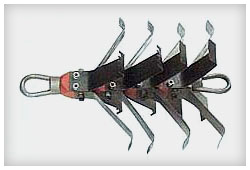

Mechanical Cleaning.

This is a self-propelled machine with rotating arms at the

front. At the ends of the arms special are aggressive blades,

these are set under tension against the pipe wall, as the

arms rotate the blades scrape the pipe wall and remove the

debris. Once the debris is on the pipe floor we then apply

the squeegee process to remove the debris from the interior

of the pipe. |