| /// LCPP, global specialist in Cement Lining. Contact us for expert advice. | |

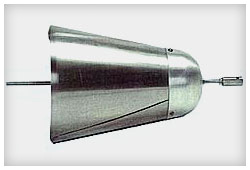

Cement Mortar LiningFor pipe sizes 3"(75mm)-24"(600mm) we use an air driven lining machine and to achieve a smooth uniform finish we use a drag trowel. Firstly we pull the hosing assembly into the pipe to be lined, the hosing assembly consists of a high-pressure hydraulic hose 1"(25mm)-2"(50mm) diameter depending on pipe size. To one side of this hose a smaller pneumatic hose is connected, usually 0.5"(13mm) this is to power the lining machine via an air compressor, on the opposite side of the hydraulic hose we connect a small wire rope 0.5"(13mm) this is connected to the hose reel winch. Once this is done we fit the lining machine and drag trowel to the hosing assembly and test to ensure the equipment is running correctly. The next stage is to mix the mortar, once the correct consistency is obtained we pump the mortar to the lining machine via the hydraulic hose, the pump is usually a triple piston pump or a rotor- stator type pump, both of these produce a smooth and constant flow. As the mortar approaches the lining machine the compressed air is turned on and the head of the machine begins to rotate at approximately 1800rpm. As the mortar reaches the rotating head of the lining machine it is fragmented and the pieces are thrown out with a centrifugal force. At this stage we begin to extract the hosing assembly from the pipe by starting the hose reel winch, this has a speed regulator thus giving us a controlled thickness of the applied mortar. The appearance of the lining at this stage is somewhat like the surface of an Orange, hence the term "Orange peel finish", for some applications this is good enough, but the majority of the time the client requests a smooth and uniform finish. This is achieved by using a drag trowel; this is connected to the front of the lining machine. The trowel is set under tension and as it is dragged in front of the lining machine it smoothes the lining giving a uniform finish. Cement Mortar Lining of Pipes 24"(600mm) and

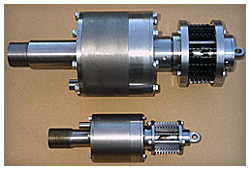

above For large diameter pipe we have four pieces of machinery and two electric generators. The Lining machine and the Intermediate loader are connected to one Generator and the Power loader and Mixer are connected to the second generator. Both generators are capable of powering all four items of machinery. However two generators are used as a precaution so that if one breaks down we can connect all four items of machinery to the remaining generator and continue with the process - this also prevents any item of machinery being stranded within the pipe. The mixer which is situated at one of the sides of the access pit is filled with up to 1.5 tonnes of material, the operator adds enough water to achieve the correct consistency, this process completed the mortar is discharged into the power loader. The power loader is a self-propelled buggy, this has a hopper to hold the mortar; as the operator drives it up the pipe there is an auger inside agitating the mortar to maintain its usable state. When the power loader reaches the intermediate loader inside the pipe the operator discharges the mortar into the hopper of the intermediate loader, the power loader then returns to the access pit where the mixer is situated in preperation to deliver the next batch of mortar. The mortar which is in the hopper of the intermediate loader is augered forward to a rotor-stator pump which is at the front of the loader, a 2"(50mm) Hydraulic hose then delivers the mortar to the rotating head of the lining machine. The mortar is then thrown out in fragmented pieces with a centrifugal force applying it to the pipe wall. The operator of the Lining machine and intermediate loader has variable speed controls allowing him to control the flow of mortar, speed of travel and speed of rotation for the lining machine head. To achieve a smooth uniform finish a set of rotary trowels are attached to the front of the machine. The operator can also adjust the tension at which the trowels are applied to the mortar, the pitch of the trowels and the speed of their rotation. Completion |

Drag Trowel Air Liner Trolley

|

| /// If you have any questions regarding Cement Lining (Cement Mortar Pipe Lining) or any of our other services, please don’t hesitate to get in touch. Tel: +1 217 6520277or Email: enquiries@lcpps.com | |

| Address: LCPP Ltd 6437 Wind Hill Drive Springfield Illinois 62711 |

|

| ENGLISH - Company Profile | Services | Cement Mortar Lining | Pipeline Cleaning | Equipment | Contact Details | Site Map ITALIANO - Profilo aziendale | Servizi | Rivestimento in Malta Cementizia | Pulitura di tubazioni | Apparecchiatura | Il contatto dettaglia | Site Map ESPAÑOL - Perfil de Compañía | Servicios | Cemente Foro de Mortero | Canalización de limpieza | Equipo | Contacto | Site Map |